|

|

|

|

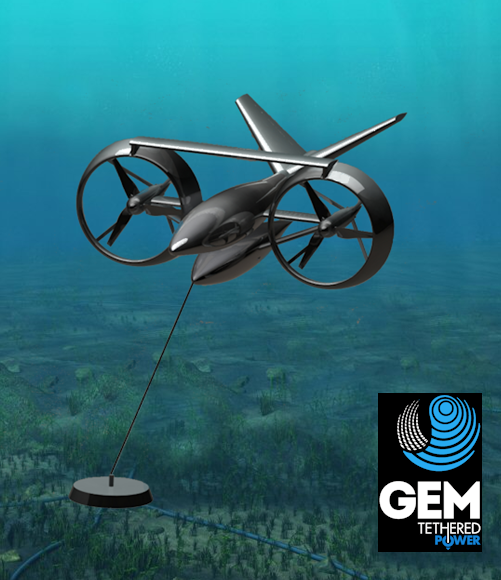

Horizontal axis marine turbine GEM

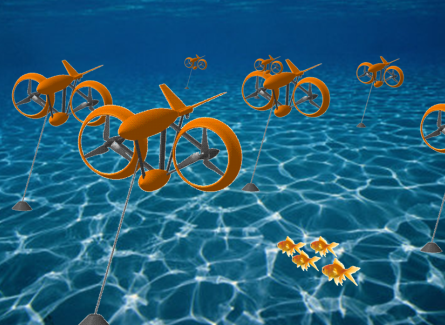

The horizontal axis marine turbine GEM “the Ocean’s Kite” is an hydrokinetic turbine designed to be driven by slow-moving flows of water, namely river, tidal or water currents in general.

The patented turbine has been developed since 2005 after a research project done in collaboration with Eng. Nicola Morrone, who is the patent holder together with Prof. Domenico Coiro, professor at University of Naples "Federico II" (Department of Aerospace Engineering) and coordinator of the ADAG Reserch Group.

|

|

|

CAD drawing |

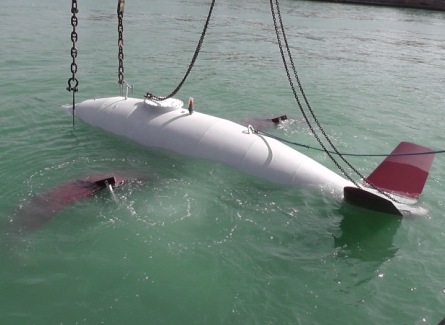

Prototype being installed at the Venetian Lagoon |

How GEM works

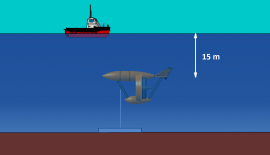

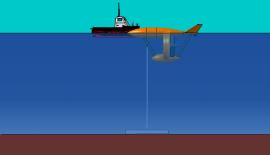

The GEM system can be easily towed to the installation site and thanks to the self-towing winch can be positioned at predetermined depth (standard depth: 13 m). In absence of current, the GEM assumes the position shown in (Fig. 1). When water current is flowing, it assumes the position as shown in (Fig. 2). For maintenance, the GEM can be easily brought to the surface simply releasing the tension of the mooring line (Fig. 3).

|

|

|

Fig.1 - without water current |

Fig.2 - presence of water current |

Fig.3 - in maintenance |

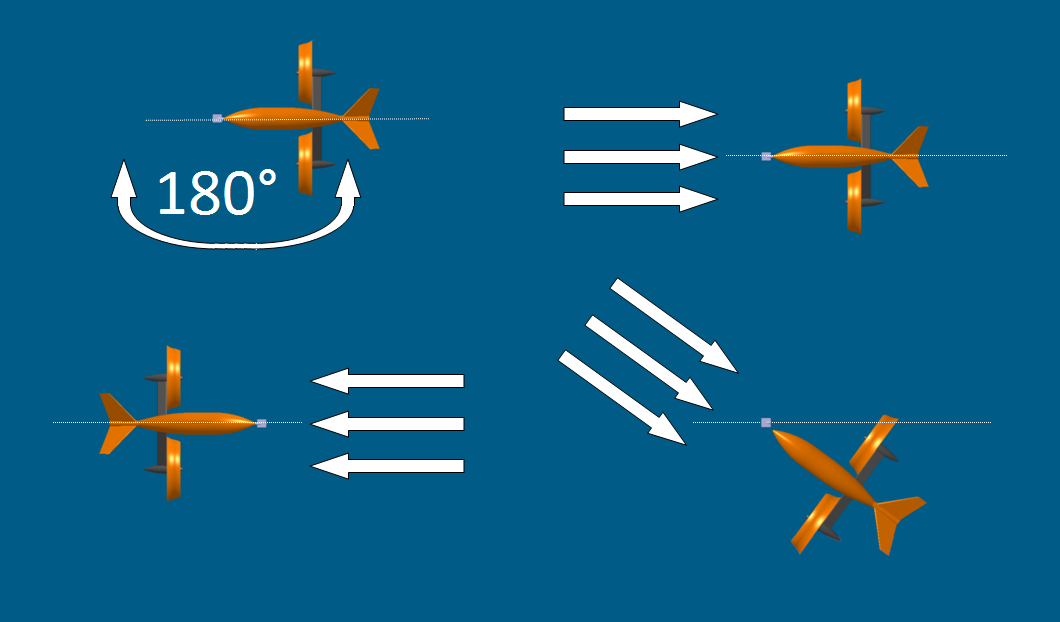

The main characteristic of the GEM, however, is its passive capacity of aligning itself along the current direction (as shown in the figure 4) and this reminds the typical behavior of a kite from which the name "Ocean's Kite". In case of need, however, it is possible to control this alignment through the aid of a controlled designed system which uses the turbines as propellers.

|

Fig.4 - Alignment to the current direction |

Performance data of 100 kW prototype |

| Total weight: 10700 kg |

| Buoyancy force: 5200 kg |

| Depth (range): 15 m to 9.8 m (without current) |

| Nominal power: 100 kW with a tidal current of 2.6 m/s |

| Three-blades 3 m diameter rotor |

| Innovating blade section profiles |

| Carbon blades - Fiberglass diffuser |

| Rated rotation speed: 65 rpm |

| Rotor Efficiency: 0.8 |

| Expected average yearly production with 2.5 m/s maximum speed site: 300 MWh |

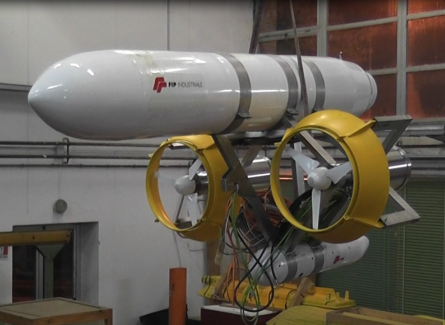

The GEM is basically made by the following parts:

- a buoyant unit;

- two contra-rotating turbines, with three blades, attached to two electrical generators, symmetrically positioned on the two sides of the frame;

- two diffusers, mounted around the two turbines, shaped to double the power output;

- a barrel-shaped container placed at the foot of the frame, and containing a winch;

- a mooring block, laid on the sea bed to which a mooring line is connected;

- an electric cable to connect the electrical generators to the grid; the electric cable running along the mooring line;

- tailplanes to provide the system stability;

- an automatic control system based on the differential turbine/propeller action to control orientation during current direction reversal.

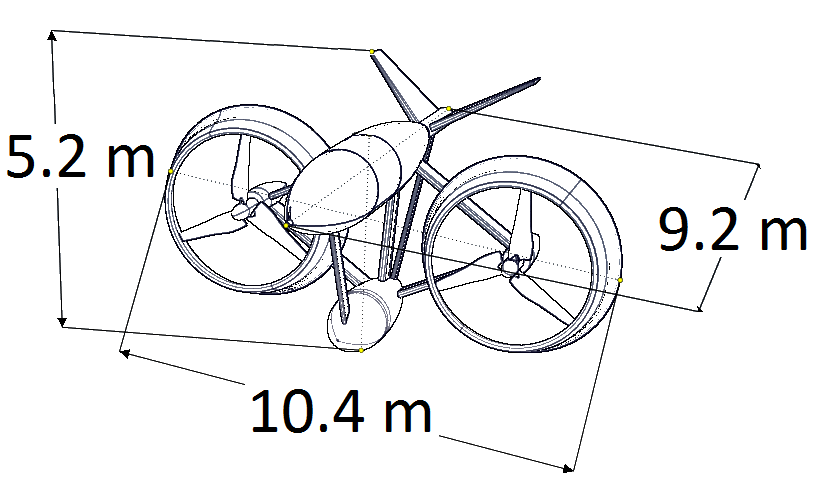

Dimensions

|

|

Innovation

Due to its special characteristics it has been patented in 2010.

Advantages

- relatively cheap

- easy to maintain

- low environmental impact

- does not disturb the navigation

- installable almost anywhere

Reserch and development

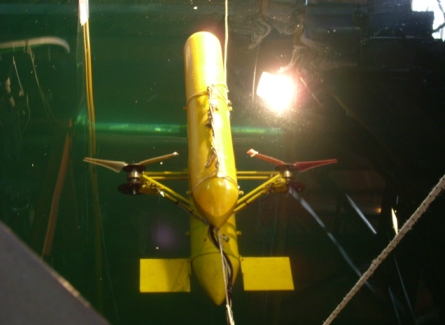

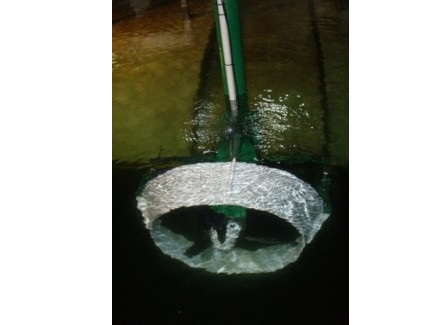

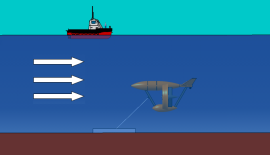

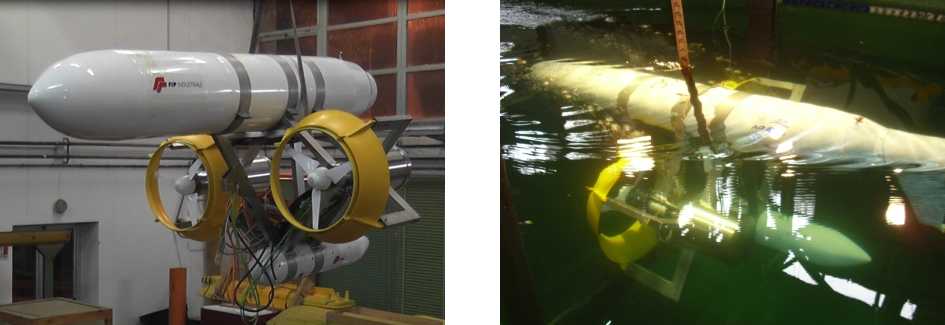

Detailed numerical analysis and two different scaled models (see figures below) have been tested in the towing tank of the "Federico II" University.

|

|

First model for towing tank tests |

|

|

|

|

Second model for towing tank tests |

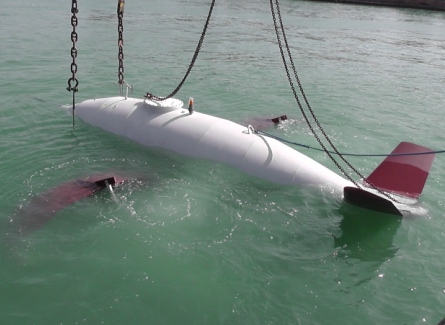

The prototype

The first full-scale GEM prototype has been built by a consortium of Venetian companies and partially sponsored by Veneto Regional and has been deployed in the Venetian Lagoon. For this prototype, the expected power is ~ 20 kW with lagoon maximum current speed of 1.5 m/s.

|

Prototype on dock in the Venetian Lagoon |

Business Plan

For a 500 kW plant installed in the Messina Strait, Italy:

- return on investment: 3.4 years

- income 20 years: 8.5 mln of €

Other images:

Video:

|

|

|

Tests in the towing tank |

Complete video history |

Deployment in the Venetian Lagoon |